Tutorial: Tank Maintenance and Troubleshooting

Welcome to MistHub's Guide to Tank Maintenance and Troubleshooting. Here we will discuss how to perform routine maintenance on your tank atomizers to keep them functioning in top condition. We will also discuss some common problems and their solutions. First, let’s take a look at how to properly use a brand new tank or a new coil you just installed in your tank.

New Tank / New Coils

Whenever you install a new coil you will want to make sure that you prime it before using it. Priming a coil will ensure that the wick in it is saturated with e-juice prior to its first use. This substantially lowers the possibility of burning your wick or damaging your coil. To prime your coil you will want to place 4-5 drops of e-juice directly into the coil head. Install the coil head by threading it into the tank’s base. You will then fill and assemble your tank. For best results you should wait 5-10 minutes before its first use. If you are in a hurry and cannot wait the 5-10 minutes you should at least wait 1-2 minutes, close the airflow and take several deep pulls without firing your device. You should be able to then re-open the airflow and use the tank normally without issue.

When To Change Coils

When exactly to change your coil heads is not quite as cut and dry because of the wide variety of different coil heads and atomizers available. Different coil for different tanks will have different life expectancies. Coil lifespan can also vary substantially because of the differences in e-juices. The PG/VG ratio of your juice and the amount of flavorings or sweeteners used in it will also play a role. As a rule of thumb you will want to change your coil head when you notice the flavor or vapor production begin to taper off or if you start to notice a burnt or burning taste.

Vape Tank Maintenance

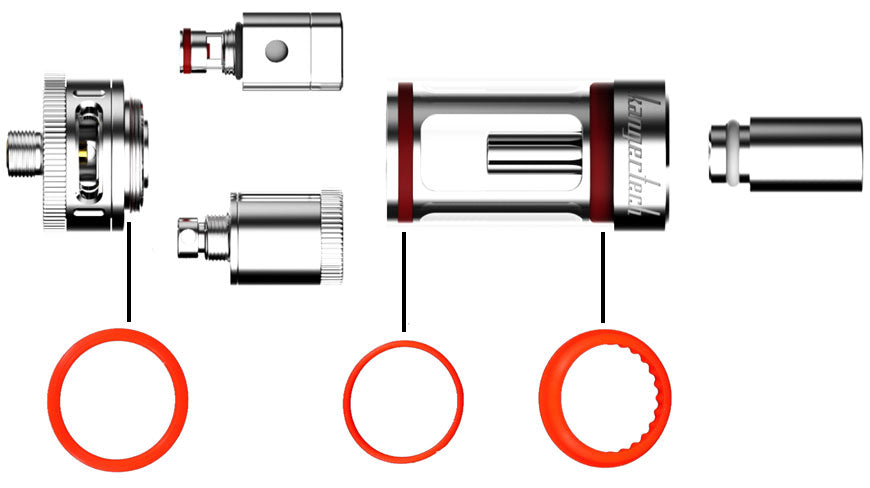

While it might seem like a complex task to maintain your tank properly it is actually quite simple. First and foremost you will want to keep it clean. At least once a month clean your tank. Start by removing the coil(s) and any O-rings. While removing the O-rings look for signs of wear or any cracks. If the any O-rings are damaged, replace them. Clean your tank thoroughly using isopropyl alcohol or warm water and a mild dish soap on both the inside and out. Make sure to pay special attention to the threads (an old toothbrush can be helpful for this part). Be sure to wash your O-rings as well. Rinse it well, then rinse it again just to be sure there is no soap or residue left behind. Once your tank is completely dry you are ready to reassemble and use it again. By keeping a clean coil in your tank and by keeping the tank itself clean and free of excess juice and debris you should have a trouble free experience when using it. Sad but true once in a while people have issues with their tanks. Let’s take a look and see what are some common causes of this and what we can do to remedy this.

Common Issues – Leaking Tank

The most common issue tank users are faced with is leaks. A leaky tank can be a real inconvenience but typically they are relatively easy to fix. Ninety nine percent of the time a tank is leaking because it is letting air in somewhere which breaks the vacuum that holds your e-liquid in the tank. First, take the tank apart inspecting all glass or plastic parts looking for any cracks. If you do not see any, check the O-rings for signs of damage or cracks. If any of the above mentioned parts are damaged in any way replace them as needed. Be sure to check and make sure the coil head itself is fully threaded into place but is not overly tight. It should be easily removable without the use of tools. If it is too tight it might have damaged the O-ring(s) on the bottom of the coil or pushed them out of place. If the O-rings on the coil are damaged replace them or the entire coil. If the tank continues to leak and all of the above has been checked it can possibly be related to a bad coil head. Over time and through use the wicking materials can break down and not hold as much juice as they once did. This causes a lack of surface tension allowing air to sneak in through the coil in which case it should be changed.

Common Issues – Tank is not firing/working

Another issue that can sometimes occur is the tank not firing. Some regulated devices might display an error message like “Check Coil” or “Check Atomizer” or it might just not work at all. If this happens to you, the first thing to do is to make sure that the device is working with another atomizer and the coil’s resistance is within the device’s operating capacity. For instance a 0.2Ω coil will not work on a device that can only fire as low as 0.3Ω. Once you are certain that the device is working and the coil in the atomizer you are using is within the device’s operating capacity we can move on. At this point we have to understand that somewhere in the circuit the electricity is not flowing properly. Fortunately this can be caused by only a few things. The first thing to check is if your installed coil is still good. To test this you can install a new coil and try it or you can try using the already installed coil on a different device or an ohm reader and check to see if it will work on it. If it reads properly on the ohms reader or works properly on a different device then the problem is with your device and not the tank. If no coil is working, you will need to try a new coil. If you have done all of the above and it still isn't working, we will then want to look at the small positive center pin found in the bottom threaded portion of the connector. The pin should sit slightly further out than the threaded portion of the connector or at very least sit flush with it. If it is pushed in you will either want to take a screwdriver and try to thread it out a little to adjust it or in the case of pins that are not threaded you can gently pry it outward to get it to the proper position. At this point the atomizer should be working properly. If it is still not working the very last thing to check is the insulator ring that the positive pin in the connector sits in. Sometime they can become brittle and crack or even melt from too high of heat. If this insulator is damaged it can be replaced, but is not commonly available and often will require the atomizer itself to be replaced. While there are other issues that can come up, they are specific to different tanks and the above information is applicable to any and every tank currently on the market. Hopefully this information will help you keep your tanks working perfectly and allow you to get them up and functioning should you run into any problems. On behalf of everyone here at MistHub thanks for reading and until next time, Vape On!

NEW: Suorin

Leave a comment